Anping Hexagonal Wire Netting Factory

Anping Hexagonal Wire Netting Factory

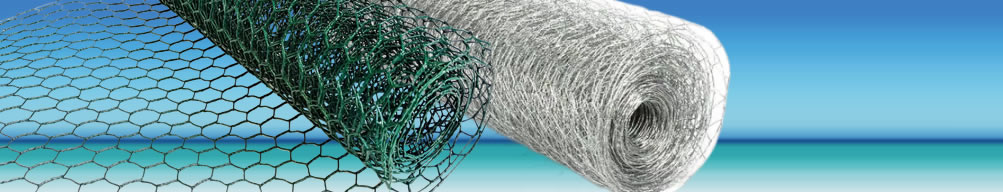

Galvanized Hexagonal Wire Netting is distinguished by its durability and adaptability, attributed to the galvanization process which involves either electro galvanizing or hot-dipping the iron wire in zinc. This treatment provides exceptional corrosion resistance, oxidation resistance, and rust resistance, making it suitable for various applications including fencing, stucco netting, and the fabrication of gabions or baskets for protective uses.

Materials: Typically made from galvanized iron wire, this netting can also be found in stainless steel, plastic-coated iron wire, or brass wire, catering to different environmental conditions and longevity requirements.

Weave Style: The common weaving styles include straight twisted, reverse twisted, and double twisted strengthened, each offering unique structural benefits. The straight twisted is standard, while reverse twisted provides added strength, and double twisted further enhances durability.

Wire Diameter: Available in a range of wire diameters from thinner gauges suitable for light applications to thicker gauges ideal for robust needs. Common diameters include:

0.9 mm (for light applications like chicken netting)

1.6 mm (suitable for medium-duty fencing)

2.7 mm (used in heavy-duty gabions)

Surface Treatment: Besides the standard galvanization, additional coatings such as PVC can be applied for added durability and color customization.

Color: Primarily available in a natural metallic silver hue due to the galvanization, but can be customized with PVC coatings in various colors according to aesthetic or visibility requirements.

Mesh Size:

Roll Size:

Customization Capabilities:

Packing: Galvanized Hexagonal Wire Netting is typically packaged in waterproof paper to prevent damage during transit and storage, ensuring it arrives in optimal condition.

Handling Instructions: Appropriate handling and installation techniques are advised to maintain the integrity of the wire mesh during unrolling and application to avoid unintended stretching or bending.

| General Specification of Galvanized Hexagonal Wire Netting | |||||

| Mesh | Min. Galv. G/SQ.M |

Width | Wire Gauge (Diameter) BWG |

||

| Inch |

mm | Tolerance(mm) | |||

| 3/8" | 10mm | ±1.0 | 0.7mm - 145 | 2' - 1M | 27, 26, 25, 24, 23 |

| 1/2" | 13mm | ±1.5 | 0.7mm - 95 | 2' - 2M | 25, 24, 23, 22, 21 |

| 5/8" | 16mm | ±2.0 | 0.7mm - 70 | 2' - 2M | 27, 26, 25, 24, 23, 22 |

| 3/4" | 20mm | ±3.0 | 0.7mm - 55 | 2' - 2M | 25, 24, 23, 22, 21, 20, 19 |

| 1" | 25mm | ±3.0 | 0.9mm - 55 | 1' - 2M | 25, 24, 23, 22, 21, 20, 19, 18 |

| 1-1/4" | 31mm | ±4.0 | 0.9mm - 40 | 1' - 2M | 23, 22, 21, 20, 19, 18 |

| 1-1/2" | 40mm | ±5.0 | 1.0mm - 45 | 1' - 2M | 23, 22, 21, 20, 19, 18 |

| 2" | 50mm | ±6.0 | 1.2mm - 40 | 1' - 2M | 23, 22, 21, 20, 19, 18 |

| 2-1/2" | 65mm | ±7.0 | 1.0mm - 30 | 1' - 2M | 21, 20, 19, 18 |

| 3" | 75mm | ±8.0 | 1.4mm - 30 | 2' - 2M | 20, 19, 18, 17 |

| 4" | 100mm | ±8.0 | 1.6mm - 30 | 2' - 2M | 19, 18, 17, 16 |