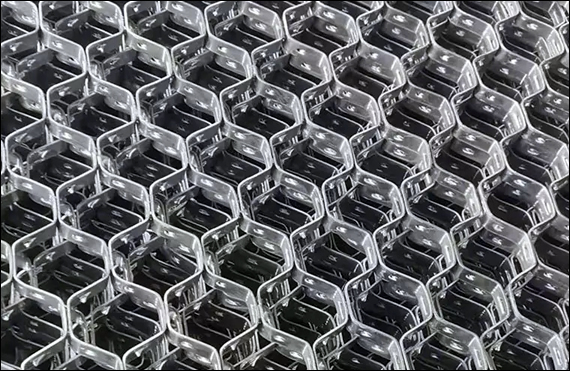

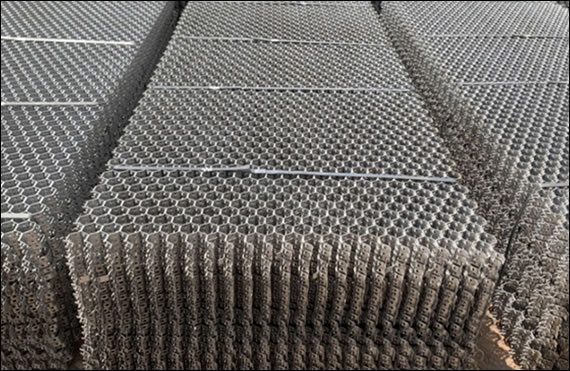

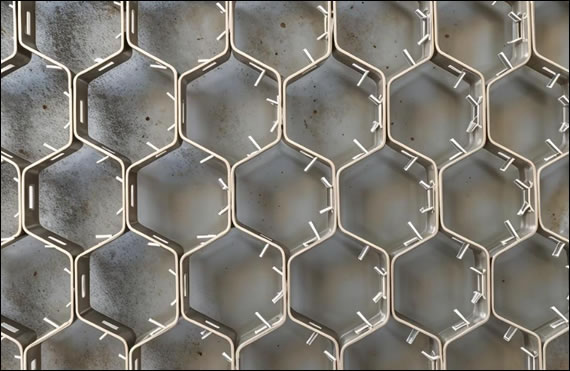

Refractory hex mesh is a type of robust hexagonal metal mesh used in refractory lining reinforcement for furnaces, reactors and kilns. Hex Mesh for refractory lining is made in 3D dimensional cellular honeycomb structure, this structure can provide robust support and excellent bonding to the refractory material, while allowing for flexibility and adaptability to various surface contours.

Hexagonal refractory mesh is adaptable to complex shapes to improve the overall performance of thermal insulation systems, main features:

- Thermal Shock Resistance: Withstands rapid temperature changes without compromising structural integrity.

- Heat Containment: The hexagonal pattern effectively traps heat, minimizing heat loss and enhancing insulation.

- Flexibility and Adaptability: Accommodates expansion and contraction of refractory materials, reducing the risk of cracking.

- Erosion and Corrosion Resistance: Provides a strong barrier against wear and chemical damage, ensuring long-term durability.

Hex Mesh is widely used in high-temperature operations, for reinforcement of Large Furnace Lining Structures Of Pipelines In Power Plants, Cement Plants, Petroleum, Smelting Plants and Steel Making Plants.

Our Capability

Hexagonal mesh designed to support refractory linings of kilns, boilers, incinerators and reactors.

Mesh Size: Hole 2cm-6cm; Mesh Thickness 1cm-2.5cm; The Plate Thickness 1mm-3mm.

Metal Materials for Hexagonal Mesh Grid in Refractory Applications:

1. Stainless Steel 304 (AISI 304)

Temperature Resistance: Up to ~870 °C (continuous)

Typical Use: General furnace linings, chimneys, ducts in mild to moderate environments

2. Stainless Steel 310 / 310S

Temperature Resistance: Up to ~1,100 °C

Typical Use: High-temperature furnaces, reformers, burners

3. Stainless Steel 316 / 316L

Temperature Resistance: Up to ~925 °C

Typical Use: Chemical reactors, acid-processing plants, flue gas areas

4. Inconel Alloys ( Inconel 600, 601)

Temperature Resistance: Up to ~1,200 °C+

Typical Use: Petrochemical, power generation, and metallurgy sectors

5. Carbon Steel (ASTM A36 /SAE 1020)

Temperature Resistance: Limited (~480–550 °C max)

Typical Use: Low-temperature or backup layers, non-critical zones

We offer the following types of hex mesh for refractory anchoring:

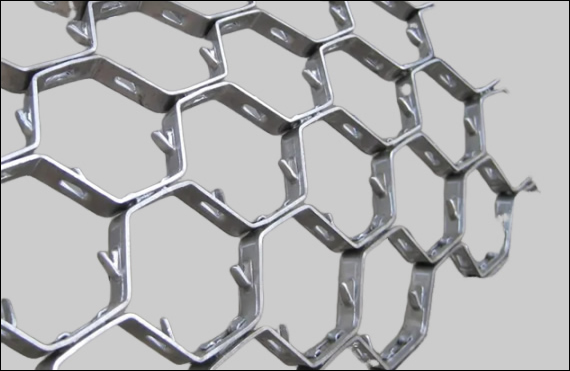

Hex mesh with bonding holes

Hex mesh with lance tabs

Offset-type hex mesh grating (honeycomb style)

Twist-pin or riveted hex mesh

Reinforced-wire hex mesh

Mesh Pattern – Hexagonal

Refractory lining mesh has an hexagonal pattern, in three-dimensional honeycomb structure. This design maximizes strength and flexibility, making it ideal for various high-heat industrial applications.

Common Sizes

Refractory Hex Mesh is available in following common sizes:

Opening Size:

- 1 inch (25.4 mm)

- 1.5 inches (38.1 mm)

- 2 inches (50.8 mm)

- 3 inches (76.2 mm)

- 4 inches (101.6 mm)

Metal Thickness:

- 0.12 inches (3 mm)

- 0.16 inches (4 mm)

- 0.2 inches (5 mm)

- 0.25 inches (6.35 mm)

Grating Panel Sizes

We can supply customized Refractory Hex Mesh to meet specific application and to ensure optimal performance and compatibility with various refractory linings.

- Custom Mesh Opening Size: From 1 inch (25.4 mm) to 4 inches (101.6 mm), adjustable in 0.5-inch (12.7 mm) increments.

- Custom Material Thickness: From 0.12 inches (3 mm) to 0.25 inches (6.35 mm), with possible increments of 0.04 inches (1 mm).

Three-Dimensional Honeycomb Structure

This structure consists of interconnected hexagonal cells, creating a robust and flexible mesh suitable for high-temperature industrial applications.

Design and Construction

- Hexagonal Cells: Each cell in the honeycomb structure is hexagonal, providing a high strength-to-weight ratio. This design distributes stress evenly across the mesh, enhancing its structural integrity.

- Interconnected Framework: The hexagonal mesh cells are interconnected, forming a continuous, seamless network. This interconnected framework ensures that the hexmesh can withstand significant mechanical and thermal stress without deforming or failing.

- Three-Dimensional Depth: Unlike flat meshes, the three-dimensional honeycomb structure has depth, allowing it to provide superior support and reinforcement for refractory linings. This depth also contributes to hexmesh’s ability to accommodate expansion and contraction of the refractory material.

Functional Benefits

- Enhanced Thermal Shock Resistance: The three-dimensional honeycomb structure allows for efficient heat transfer while providing excellent resistance to thermal shocks. The interconnected hexagonal cells can expand and contract, reducing the risk of cracking under rapid temperature changes.

- Improved Heat Containment: The hexagonal mesh cells trap small pockets of air, which act as insulating barriers. This insulation minimizes heat loss and helps maintain a stable temperature within the refractory lining, enhancing energy efficiency.

- Superior Erosion and Corrosion Resistance: The robust interconnected framework provides a strong barrier against erosion and chemical corrosion, hence ensures the longevity and reliability of the refractory lining, even in harsh industrial environments.

- Flexibility and Adaptability: The three-dimensional honeycomb structure is inherently flexible, allowing it to conform to various shapes and surface contours.

Stainless Steel Hex Mesh for Refractory Lining

Hex Mesh 2mm x 19mm SS304

Materials for Refractory Lining:

| Item No. | Description | Material |

| 01 | SS Hexmesh, H=19mm, T=2mm | SS 304 |

| 02 | Hanging Packing Class A | Rescobond AA 22 S |

| 03 | Edging Bar | SS 304 |

| 04 | End Tabs | SS 304 |

| 05 | End Tabs | SS 304 |

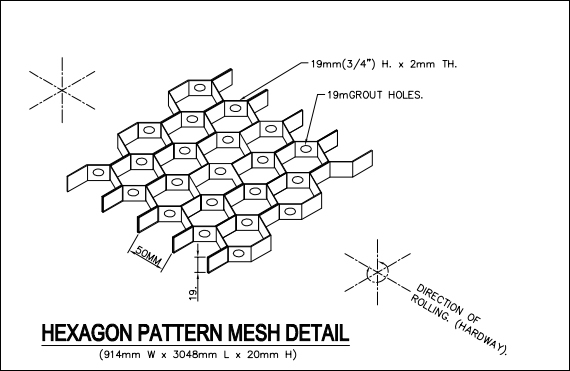

Hexagon Pattern Mesh Details

Grout holes for facilitating enhanced adhesion and integration with the refractory material.

Specifications:

- Hexagon Size: 19 mm (3/4″) in height

- Wire Thickness: 2 mm

- Mesh Height: 20 mm available

- Grout Holes: 19 mm diameter

- Mesh Spacing: 50 mm

- Direction of rolling (hardway)

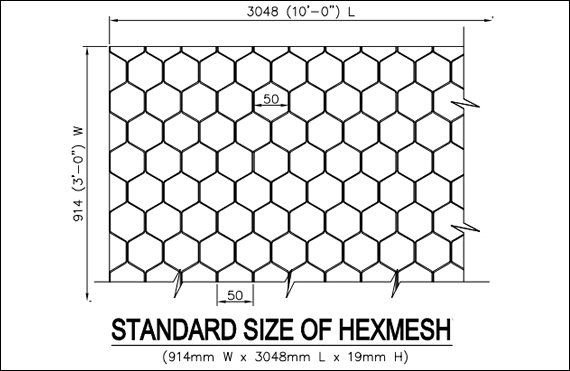

Standard size of hexmesh

914 mm W x 3048 mm L x 19mm H

- Width: 914 mm (3′)

- Length: 3048 mm (10′)

- Mesh Height: 19 mm

- Mesh Spacing: 50 mm

- Mesh Pattern: Regular hexagonal

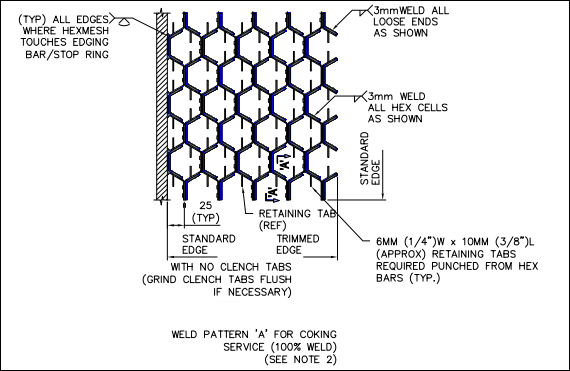

Weld Pattern of HexMesh:

3mm Weld all loose ends

3mm Weld all hex cells

Hex mesh 100 percent weld ensures maximal adhesion and support, ideal for severe service conditions such as in coking operations.

Hex Mesh for Coking Service Specifications

- Weld Requirement: All hex cells welded, weld size ≤3mm

- Retaining Tab: 6mm x 10mm (approximately 1/4″ x 3/8″)

- Edge Treatment: Standard edge and trimmed edge without clenched tabs; tabs to be ground flush if necessary

- Additional Features: All edges where hex mesh touches edging bar/stop ring

- Special Weld Pattern: This type for coking service requiring 100% weld coverage

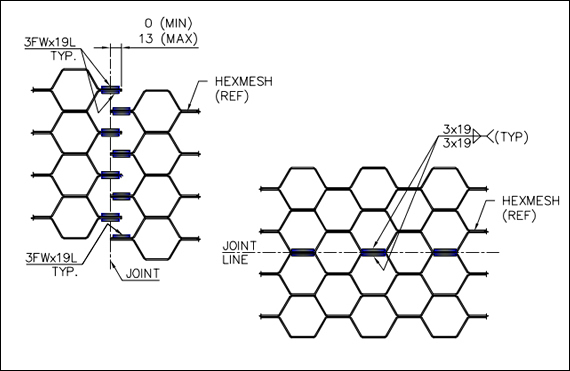

Joint Line of Hex Mesh

Precise alignments for enhanced mechanical stability in refractory linings.

Hex Mesh Configuration and Alignment:

- Hexagonal Opening Size: Minimum 0 mm, Maximum 13 mm at joint

- Joint Configuration: 3F W x 19L (Typical)

- Wire Configuration at Joints: 3 x 19 gauge (Typical)

- Wire Configuration at Joint Line: 3 x 19 gauge (Typical)

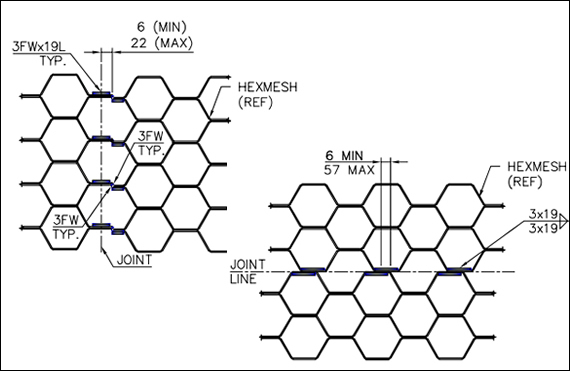

Standard Hex Mesh Configuration

Standard hex mesh layout for general refractory applications:

Hexagonal Opening Size: Minimum 6 mm, Maximum 57 mm

Joint Configuration: 3F W x 19L (Typical)

Wire Configuration at Joints: 3F W (Typical)

Maximum Joint Length: 22 mm

Wire Gauge: 3 x 19 gauge

Notes of construction:

- All measurements are provided in millimeters (mm) .

- Ensure hexmesh fits against the lining surface of the ring and outlines the boundary of the plate.

- Install hexmesh tightly against the surface of the plate using the rolling method indicated in the diagram.

- Test the hexmesh and edging bar with a 500gm hammer from a height of 300mm to check for any loose or broken welds, which must be removed and replaced.

- Visually inspect the welds to ensure they adequately penetrate through the hexmesh and into the underlying metal.

- Use the same material for the edging bar, end tab, punch tabs, and corner rabs as used for the hexmesh. Ensure all parts meet client specifications.

- Minimize the length of the hexmesh to prevent overheating during refractory application.

- Ensure all bridging pieces are welded securely to the shell.

- Wire brush or clean the entire surface area before applying refractory material.

Bar Grating Clinched Grid Hex Mesh Type

Honeycomb Refractory Support for linings in high-temperature furnaces, kilns, and ducts.

Material: Stainless Steel, Type 304

Surface Finish: Mill Finish, Smooth Surface

Bar Type: Rectangular Bars

Bar Dimensions: Height: 3/4 inch (19.05 mm), thickness: 0.080 inch (2.03 mm)

Bar Spacing: 1-7/8 inch (47.63 mm) center-to-center spacing

Grid Pattern: Clinched into hexagonal (honeycomb) grid

Panel Size: 36 inches × 120 inches (914 mm × 3,048 mm)

Open Area: 87%

Supply to India

Hex Mesh Low Carbon Steel AISI C1010 and SAE 1020

Hexagonal Metal Mesh / Tortoise Anchorage AISI C1010

Material: AISI C 1010 US Standard Low carbon steel

Size: 50X19X2MM

Opening: 50 MM

Depth: 19 MM

Flat bar thickness: 2 MM

Supply to Singapore

Hex Opening Mesh Panel SAE 1020 Low Carbon Steel

Hexsteel Grade Height 3/4'x2mm Mesh Hexag. 47mm - Half-moon 1500x3000 SAE 1020

Panel Type: Half-moon edge panel for circular linings

Sheet Size: 1500 mm × 3000 mm

Bar Height: 3/4 inch (≈19 mm)

Bar Thickness: 2 mm

Mesh Type: Hexagonal

Hex Opening Size: 47 mm (flat-to-flat)

Surface Finish: Mill finish

For refractory anchoring system in semi-cylindrical surfaces

Hexsteel Grade Height 3/4'x2mm Mesh Hexag. 47mm SAE 1020 8mm

Material: SAE 1020 (low-carbon steel)

Bar Height: 3/4 inch (≈19 mm)

Bar Thickness: 2 mm

Bar Width: 8 mm (rectangular bar cross-section)

Mesh Type: Hexagonal pattern

Hex Opening Size: 47 mm (flat-to-flat)

Surface Finish: Mill finish

For high-temperature lining support on flat surfaces and vessel walls

Supply India

Hex Mesh, Archor Rod and Reinforcing Fibers for Refractory Lining Systems

We supply Refractory Materials for complete refractory anchoring system:

Hexmesh

Anchor Rods (V-type and S-bar)

Reinforcing Fibers

Hexagonal Mesh Panels

Internal linings of vessels and ducts

SS304 and AISI 410S, 14 Gauge

Hexagonal Mesh, Thickness: 25mm(14Gauge (2mm)) /Material : AISI 410S

Hexagonal Mesh, Thickness: 19mm(14Gauge (2mm)) /Material : AISI 410S

Hexagonal Mesh, Thickness: 25mm(14Gauge (2mm)) /Material : SS 304

Hexagonal Mesh, Thickness: 19mm(14Gauge (2mm)) /Material : SS 304

Metal Reinforcing Fibers MATERIAL: SS304

Stainless steel fibers, 19mm length, 0.5mm thick, ASTM A820 Type III

To be mixed into castable or gunned refractory materials to enhance structural integrity.

V-Footed Anchor Rod (TP304 Stainless)

to be used with hex mesh for insulation linings, Angles 60° and 40°, various lengths and base sizes:

ANCRAGE TYPE V/U ET TYPE

1 V-Footed Anchor Rod(Angle 60°),ф8X100X87,Base=25mm,(R=13XR=10)Material: ASTM A479-TP304, with plastic cap L=13mm

2 V-Footed Anchor Rod(Angle 60°),ф8X75X62,Base=25mm,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

3 V-Footed Anchor Rod(Angle 60°),ф8X49X49,Base=25mm,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

4 V-Footed Anchor Rod(Angle 60°),ф8X80X74,Base=25mm,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

5 V-Footed Anchor Rod(Angle 60°),ф8X138X125,Base=25mm,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

6 V-Footed Anchor Rod(angle 40°),Base=50mm,ф8X380X367,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

7 V-Footed Anchor Rod(angle 40°),ф8X362X349,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

8 V-Footed Anchor Rod(angle 40°),ф8X362X240,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

9 V-Footed Anchor Rod(angle 40°),ф8X362X247,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

10 V-Footed Anchor Rod(angle 40°),ф8X284X271,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

11 V-Footed Anchor Rod(angle 40°),ф8X262X145,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

12 V-Footed Anchor Rod(angle 40°),ф8X229X149,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

13 V-Footed Anchor Rod(angle 40°),ф8X172X134,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

14 V-Footed Anchor Rod(angle 40°),ф8X172X53,(R=13XR=10)en ASTM A479-TP304, avec bouchon en plastique de L=13mm

Refractory Support Bar, S-Bar, Length:67mm /Thk : 2mm with 2X(R=10,L=19mm) /Material : A479-SS304